Electrical cabling is often overlooked in motion system design. If you use something other than industrial cabling (which is designed to flex continuously) premature failures can result.

Continuous-flex cables are designed to cope with the tight bending radii and physical stress associated with motion control applications. A regular cable typically manages 50,000 cycles, but a flexible cable can complete between one and three million cycles.

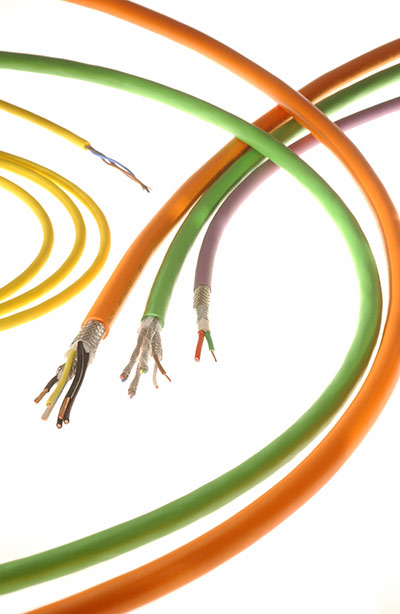

Flexible cables can be divided into two types: those with conductors stranded in layers inside the cable, and those that have bundled or braided conductors.

Cables with stranded layers are easier to produce, and usually less expensive. The cable cores are stranded firmly and left relatively long in several layers around the center and are enclosed in an extruded tube-shaped jacket. However, this design can lead to core rupture.

Bundled designs feature braided conductors that surround a tension-proof center. A pressure filled outer jacket ensures the cores cannot twist, so these cables are often stiffer than standard cables, but last longer in constant flex applications.

Flat cables can incorporate power, signal, and video conductors as well as air or liquid tubing and fiber optics in a single compact cable suitable for continuous flexing.

Flat cables with silicone jacketing resist abrasion and other harsh environmental impacts and will even self-heal minor nicks.

To select the right cables, determine the application type, such as whether it will be stationary or moving, and what type of movement it is—flexing, torsion, or both?

If there is bending or motion involved, the bend radius must be specified. The bend radius depends on the gauge of the wire and the kind of conductors used in the cable. With continuous flexing, conductors containing multiple strands of fine-gauge wire generally last the longest.

Leave a Reply

You must be logged in to post a comment.