Electromagnetic interference (EMI) is prevalent throughout the factory floor. This is why data and signal cables are usually protected with insulated conductors and wrapped with a conductive layer. Shielding reduces electrical noise and reduces its impact on signals and also lowers electromagnetic radiation. Shielding prevents crosstalk between cables near each other. Shielding not only protects cable but it can also protect machinery and people as well.

Power cables are constructed to be electromagnetic compatible (EMC) to minimize noise generation, which affects many other systems like radio and data communication.

Communication cables are shielded to prevent the effects on the data transmitted from EMI. To further prevent cross talk and coupling, communication cables are also paired and individually shielded.

In some applications, such as those needing servo cables, double or even triple shielding is required: around individual conductors, around twisted pairs, and around the entire cable.

Some applications do not require shielded cables. For example, if a cable will be used in a cabinet or otherwise away from other sources of noise, it does not need to be shielded, as it will be protected from noise and EMI already.

Types of shielding

Cable shielding uses either a braided, spiral design or metal-coated Mylar or foil shield. The shielding wraps around each conductor to mitigate noise by 85% to 100%, depending on the configuration. The maximum shielding a braided shield can have is 90%. Spiral shields can offer 98%, while metal-coated Mylar can deflect 100% of EMI.

Using a thin layer of Mylar or aluminum foil eliminates the gaps you may encounter with braided designs. The foil is attached to a polyester backing to provide 100% coverage. However, because it is thin, it can make applying connectors a challenge. Foil shielding can also be damaged in high-flex applications, so spiral or braided designs work best there.

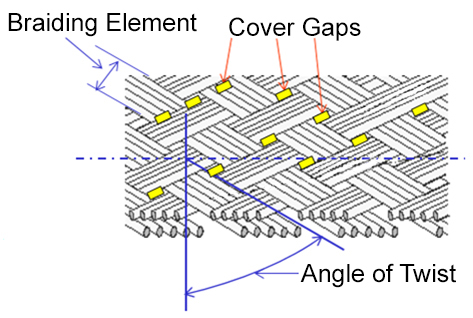

Just as described, braided shielding is made of a mesh of bare or tinned copper wires woven together. It is easy to terminate when crimping or soldering a connector. Because of the braiding, small gaps of coverage do occur, thus resulting in the only 90% shield rating. If the cable is not moving or flexing, this coverage should be sufficient. However, the braided design does add cost and weight to the final design.

If an environment is extremely noisy, a cable may use multiple layers of shielding with both the braided and foil designs. Sometimes pairs of wires are shielded individually in addition to the entire cable being shielded. This is done to prevent crosstalk between pairs.

Besides the braid covering, the maximum admissible diameter of the single strand of braid and the angle of twist to the axial axis of the conductor are also determined in the manufacturing. The thinner the single strand and the smaller the angle of twist, the more flexible is the cable. However, the diameter of the single wire is restricted due to the mechanical requirements.

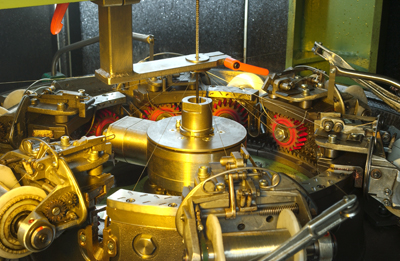

A cable shield consists of a respective amount of strands, depending on the braiding machine (16, 24, 32). The total amount of strands equals the number of strands in a braiding element times the amount of elements. The strand diameter, the angle of twist and the folding number also determine the density of a shield. The single strands are combined to make larger strands. The larger strands are then unwound from the coils and are mounted on special braiding machines for stranding construction around the conductors.

Connecting shielded cables

As noted above, certain designs accommodate crimping or soldering of connectors easier than others. However, it is important to note that the connector, too, must offer similar ratings as the cable for effective shielding. Finally, it is important the cable be grounded at one end to eliminate the potential for noise loops.

Thanks to Kevin Siegel Communications Manager at Helukabel USA for contributing to this article.

[…] Using correct cables and cabling may be the single most important aspect to setting up a video preservation rack. Know your source signal (composite, component, or Y/C ) and send it out using only the highest-grade shielded cable. Remember: Shielding reduces electrical noise and…its impact on signals and…lowers electromagnetic radiation. Shielding prevents cross-talk between cables… Shielding not only protects cable but… machinery and people as well. [1] http://www.wireandcabletips.com/importance-shielding-cabling/ […]