Contributed by Horst Messerer • Product Manager • Helukabel

As more manufacturers join the SPE Alliance, questions about its functions and uses abound. Here’s a look at critical information about Single Pair Ethernet.

Single Pair Ethernet

What is Single Pair Ethernet (SPE) and why do we actually need it? Industrial use of Ethernet has been established for a long time now. These are the classical questions a person asks when confronted with the topic of Single Pair Ethernet for the first time.

Historical facts

The first data cables were PVC-insulated single conductors that were stranded into pairs to prevent possible faults.

Later, it was ascertained that low-capacity1 insulation (e.g. polyethylene) has improved electrical properties, enables longer ranges, and can reduce the use of ferrites (magnets that contribute to fault-free data transmission) during cable assembly. This was common practice in analog technology; and to control each function and each device of a system, a separate pair was required.

This changed with the advent of digital technology. Impedance, cable attenuation, near-end crosstalk and other properties were defined as cable parameters, and bus technology found its way into automation, system and mechanical engineering. Suddenly, many devices of a network could be controlled with one cable pair, e.g., PROFIBUS. This succeeded thanks to digital technology and addressing each individual device. The data transmission of bus cables, however, was still very slow in comparison to today‘s possibilities, and achieved a maximum of 20 Mbit.

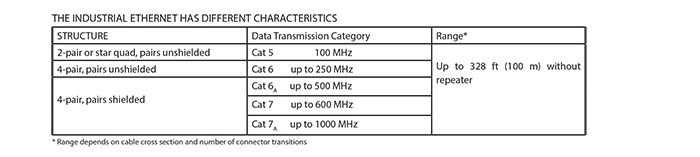

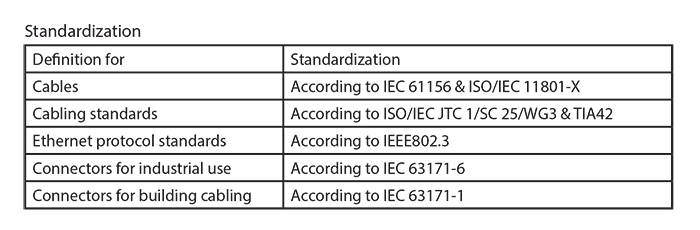

Ethernet, a uniform data network for networks (LAN technology), was originally used exclusively for office communication. It was not until the turn of the millennium that industrial equipment, connectors and Ethernet cables were made suitable for industrial use. The Industrial Ethernet was born.

In 2015, the automotive industry started to rely more heavily on Single Pair Ethernet. The advantages are that it is space-saving, high-performance, and light. It is ideal therefore for the enormously increased data rates caused by cruise control, autonomous driving, or the camera system in the vehicle. In the car, an unshielded cable is usually used for 100BASE-T1, as the application lengths are < 50 ft (15 m).

In order to make the Single Pair Ethernet suitable for industrial use, and to help shape the technological changes, Helukabel joined the SPE Industrial Network e.V. (single-pair-ethernet.com)

Will Single Pair Ethernet replace the classical Industrial Ethernet?

The short answer to this question is no. The classic two- and four-pair cables have advantages when it comes to range, reaching up to 328 ft (100 m) without a repeater. A further aspect is that four-pair cabling still guarantees a residual transmission of 100 Mbit in the case of failures, or when a pair is mechanically overloaded. With Single Pair Ethernet, the analog sensor system could be digitalized and the comparatively slow bus technology gradually replaced. Furthermore, Single Pair Ethernet offers additional advantages compared to the classic Industrial Ethernet, especially when it comes to small systems. These include thinner bending radii, smaller cables and transmission rates of up to 1 Gbit on a single pair. Space advantages like these are decisive for small cameras, in particular, or for cobots, i.e., collaborative robots that work alongside humans.

How does one-pair data transmission actually function?

The classic Ethernet works with a four-pair Cat. 5 cable within a frequency range of up to 100 MHz. The individual pairs send/receive interchangeably, up to 1 Gbit to be transmitted. In the case of Single Pair Ethernet, only one pair is available. In order to be able to transmit 1 Gbit, chip sets with a range of up to 600 MHz are used. Some frequencies in the wide spectrum receive, while other frequencies send… This is how SPE works.

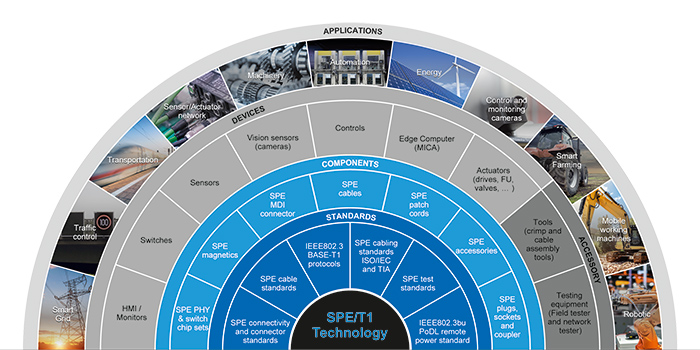

Why is Single Pair Ethernet of interest for industrial use?

Single Pair Ethernet enables consistent data transmission up to field level. In contrast to before, only one pair is required to transmit the signals (instead of the previous two or four pairs).

In this way, Single Pair Ethernet matches the industrial requirement profile exactly, and offers the following advantages (compared to the classical Industrial Ethernet):

In this way, Single Pair Ethernet matches the industrial requirement profile exactly, and offers the following advantages (compared to the classical Industrial Ethernet):

• Thinner cables

• Lower cost of assembly

• Less space requirements, lower weight, smaller laying system possible, if necessary

• Smaller bending radii and smaller drag chains in the case of continuouslymoving applications

• Lower caloric load, less smoke development

• Less materials like copper or plastic => protects resources

Furthermore, despite Industrial Ethernet, current digital bus technology and analog sensor technology is used at the lowest level. Single Pair Ethernet lays the foundation for the digitalization of the previous sensor technology, so that the Ethernet can be used right up to the sensor.

Application areas

Single Pair Ethernet covers the requirements of diverse industries. This means that cables are used depending on the application, e.g., for fixed installation, for flexible use, or for highly dynamic applications, such as in drag chains or in robots. Jacket materials can be PVC, FRNC, or PUR, depending on customer needs and application. High-temperature materials such as FEP may also be implemented.

Factory automation — In addition to the options for expanding or substituting SPE in classic sensor and Industrial Ethernet cables, there will also be future possibilities with CAN bus working with SPE 1000Base-T1 up to the 130 ft (40 m) range. As well as saving on weight, this will enormously increase data speed.

Process Automation — With 10BASE-T1L, SPE also offers a quantum leap in process automation, where for decades data rate transmission has been 31.25 kBit. For example, SPE10BASE-T1L 10 Mbit enables video transmissions from security cameras up to max. 3,280 ft (1,000 m) (this is not possible with PROFIBUS PA).

Power Over Data Line (PoDL)

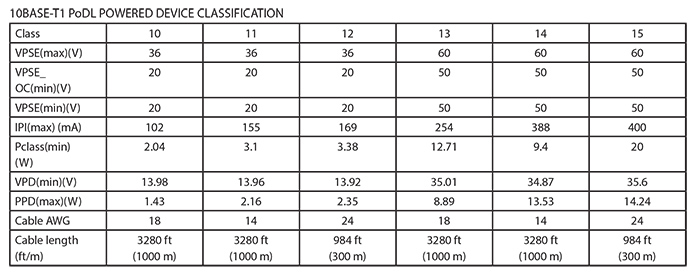

Thanks to PoDL, Single Pair Ethernet also makes power supply possible parallel with data transmission. The two charts of classifications provide an overview for end devices up to maximum 50 W power transmission.

Hybrid cables for larger power requirements

If the PoDL classifications up to maximum 50 W do not cover the power requirements of the device, SPE hybrid cables and M8 connectors provide the ideal solution with more power. In this case, the cable contains an Ethernet pair with AWG 22-24 and two AWG 18 power conductors that provide up to 400 W at 60 V over a distance of 130 ft (40 m). It is mandatory to shield the data element pair. It is also possible to have an overall shield as well.

Connector Assignment:

Helukabel

helukabel.com

1 Low capacity insulations such as polyethylene store less energy and provide a better, more efficient, data transmission performance.

Leave a Reply

You must be logged in to post a comment.