Understanding the key factors that go into selecting fiber optic cabling for sensing will ensure the most reliable and easy-to-maintain system that reduces your maintenance operations.

By Jean Baptiste Gay, Project Manager, Fischer Connectors

Fiber optic cabling is mostly known for being the ideal solution to carry large amounts of data over long distances. However, fiber optics can also be used to gather information about the environment. The physical properties of light into the fiber can be affected by strain, temperature or sound. Several technologies enable either local measurement points or distributed measurement all along the fiber. These technologies rely on the wave properties and quantum interactions of light with the fiber optic core matter.

Fiber optic cabling is mostly known for being the ideal solution to carry large amounts of data over long distances. However, fiber optics can also be used to gather information about the environment. The physical properties of light into the fiber can be affected by strain, temperature or sound. Several technologies enable either local measurement points or distributed measurement all along the fiber. These technologies rely on the wave properties and quantum interactions of light with the fiber optic core matter.

We can distinguish two types of sensing:

1. Local measurement points

• The sensor is localized along the fiber at chosen measurement points

• Typical: – FBG (Fiber Bragg Grating)

2. Distributed sensing

• The fiber itself is the sensor, with sensing occurring all along the fiber

• Typical: Rayleigh, Brillouin, and Raman

Local measurement points

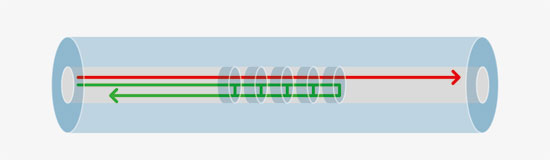

Local measurements over a fiber are achieved by using fiber Bragg sensors (or FBG for Fiber Bragg Grating). The technology is based on small (~5 mm) arrays of laser-induced discontinuities (Figure 1) along the fiber core that constructively interfere at a specific wavelength, which then acts as a mirror tuned for that specific wavelength.

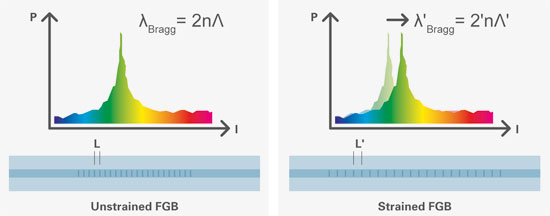

The system uses a tunable laser to scan a spectrum range while checking for reflected light. The exact reflected wavelength is measured via a spectrometer and stored as the initial value. When a strain is applied to the fiber, the fiber will stretch according to its elastic properties. This will cause the FBG to change its step (“L” in Figure 2) between the discontinuities. Therefore, the associated reflected wavelength will be shifted and its measurement will be used to quantify the strain. If the fiber is mechanically linked to the material, the strain information will be measured. If the fiber is not mechanically linked to the material, the FBG will act as a simple temperature sensor (as the elongation of the fiber will only be induced by thermal expansion).

For FBG to work, the use of single mode fiber is mandatory. As the information is contained in the light reflected by the FBG, the requirement for ultra-low return losses is a general concern when using this technology.

Distributed sensing

Distributed sensing, unlike FBG sensing, uses the whole fiber as a sensor. No specific modification is needed on a standard telecom fiber for the system to work. It is based on the physical interactions of light along the fiber.

Light backscattering is the main physical interaction that drives distributed sensing measures. Backscattering occurs when a photon encounters an impurity inside the fiber core. This causes the light to be sent backwards into the fiber in the direction of the light source (Figure 3).

These small impurities are evenly distributed along the fiber, so when a discontinuity (externally induced by strain, temperature, vibration, etc.) is applied to the fiber at a certain location, the impurities density is modified. This causes a change in the backscattering intensity at that location. By measuring the time of flight (of a light pulse), it is possible to know precisely where (distance from the source) the discontinuity occurs (Figure 4).

As backscattering represents an extremely low amount of returning light, measurements must be taken over a long period of time to collect enough information for a precise measurement. Consequently, acquisition time is very low.

Different types of backscattering

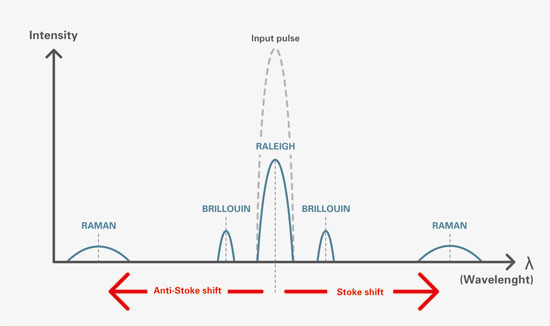

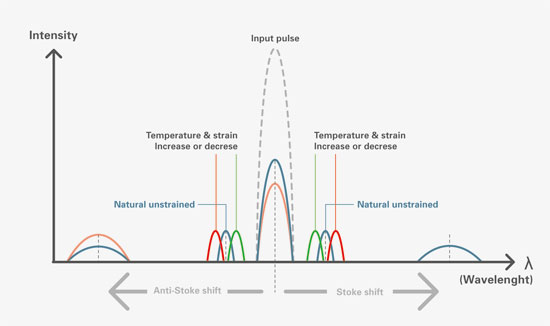

Following a specific monochromatic input pulse, the resulting backscattered light that comes backwards inside the fiber has the following profile (Figure 5):

Same wavelength—Rayleigh backscattering

Positive (Stoke) and negative (anti-Stoke) low shift—Brillouin backscattering

Positive (Stoke) and negative (anti-Stoke) high shift—Raman backscattering

Rayleigh backscattering

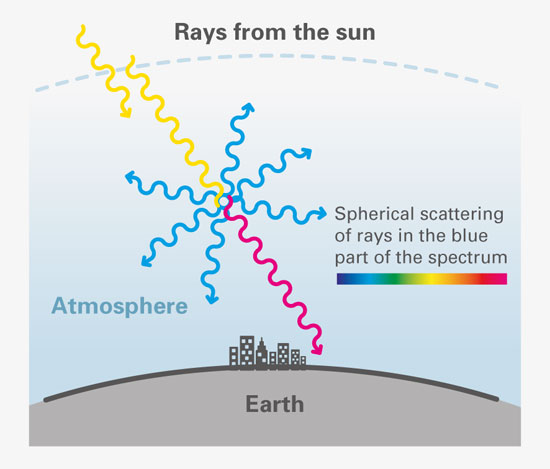

Rayleigh scattering is a phenomenon you experience nearly every day. It is the effect that makes the sky look blue (Figure 6).

Rayleigh scattering describes the elastic scattering of light by spheres which are much smaller than the wavelength of light. The most important discontinuity inducing Rayleigh backscattering into fiber optics results from small variations in the core refractive index. These discontinuities are, by construction, evenly distributed along the fiber and therefore induce a constant backscattering noise back to the source (Figure 7).

Rayleigh backscattering is the technology an OTDR (optical time-domain reflectometer) relies on. Most fiber optic telecom technicians use it every day to test and troubleshoot fiber optic links. It adds a time domain calculation to the Raleigh backscattering effect, enabling the exact location of a failure on the line to be found using the time of flight (Figure 4).

Brillouin backscattering

Brillouin backscattering occurs due to the interaction between the light and acoustic phonons travelling in the fiber (caused by thermal excitation or strain). As the light is scattered by a moving entity (phonon), its frequency (wavelength) is shifted by the Relativistic Doppler effect (by around 10 GHz or 0.1 nm for a 1550 nm wavelength). Light is generated at both at positive (Stoke) and negative (anti-Stoke) shifts to the original optical wavelength (Figure 8). The intensity and frequency shifts of the two components are dependent on both temperature and strain. By measuring the shifts’ absolute values, the two parameters can be calculated. However, as both temperature and strain are convoluted in the measured value, Brillouin-based systems usually consist of two fibers: one is linked to the structure, measuring both strain and temperature, and the other one is free from the structure, measuring temperature only and being used as a temperature compensation for the strain measurement.

Raman backscattering

Raman scattering occurs when light is scattered due to interaction with molecular vibrations in the fiber. As with Brillouin scattering, positive (Stoke) and negative (anti-Stoke) shift components are produced and these are shifted from the wavelength of the incident light. By measuring the ratio in intensity between the Stoke and anti-Stoke components, an absolute value of temperature can be measured (Figure 9). Usually only the anti-Stoke component, which is the most temperature dependent, is monitored. Raman backscattering is exclusively temperature dependent, so only one fiber can be used (unlike Brillouin).

Interconnecting solutions

Fiber optic sensing technologies require top-of-the-range optical performances to work flawlessly (with a good signal-to-noise ratio). Insertion loss must be as low as possible and return loss is a critical concern, as the returning light contains information about the measurement. Optical connectors are generally specified in APC end faces for Single mode, as they guarantee the lowest possible return loss. Manufacturing a good and reliable APC termination requires top-of-the-range polishing equipment and skilled operators. Each termination must be certified in terms of end-face geometry to guarantee good physical contact (thus ensuring ultra-low return losses). On the connector construction stand point, each APC terminus has to be keyed properly and the shell must have been designed with fiber optic in mind, since the overall tolerances must meet the termini design requirements.

Sensing and instrumentation are by nature exposed to environmental constraints; the cable assemblies and connections that carry the measurement therefore have to be able to withstand these conditions. This can be challenging and requires premium materials and high-quality solutions. Having a strong, reliable, easy-to-maintain and quickly deployable fiber optic solution is the key to success.

Ease of maintenance is an important factor, as associated downtimes can lead to considerable loss of earnings when the sensing system is a critical part of the security loop associated with the main production.

Fischer Connectors can provide premium, high performance, robust fiber optic cable assembly solutions that are designed for extreme environmental resistance and ease of use, due to its unique push-pull locking system and easy maintenance.

For example, its Fischer FiberOptic series offers a ready-to-use solution for field deployment. Its ruggedness ensures quick and safe connections, even when handled by untrained operators. Its extreme cleanability, coupled with its removable sleeve holder, enables a first level of maintenance even in the field. You can also obtain pre-terminated cable assemblies in single Mode APC and other fiber types, for perfect integration into sensing applications. The rugged and sealed bodies ensure a high degree of mechanical protection, while making no compromise on optical performance, thanks to their shell design and best-in-class butt joint termini. Available in 1, 2 and 4 fibers, the range features a wide choice of body styles to fulfill all your integration needs.

In March 2016, Fischer Connectors launched its new single fiber optic connector (FO1) within its Fischer FiberOptic Series. This miniature, lightweight, rugged connectivity solution is easy to use and ensures premium performance even in harsh environments. The FO1 connector is also available either in pre-configured reels or integrated into custom assemblies for applications in instrumentation and sensing – to name only a few of the various fields for which this new product is ideally suited.

This new connector fulfills the growing market need for higher data transmission rates over long distances, while reducing space and guaranteeing performance by means of rugged miniature solutions.

Fischer Connectors

fischerconnectors.com

Leave a Reply

You must be logged in to post a comment.