By Frances Richards, Contributor

To put it simply, excess voltage drop can reduce the operating efficiency of motors, lights, appliances, and other electrical equipment. If too much voltage is lost while passing through wires, equipment may not function properly, or at all. For certain equipment such as pumps, large motors, or machines that use compressors, even a small loss of voltage can be problematic. Keep in mind that voltage drop also generates heat, which can build up in wires or cables and damage the insulation, ultimately leading to safety issues such as fire and shock. Let’s take a look at the four main factors that affect voltage drop, and how to keep it to an acceptable minimum — defined by the National Electrical Code (NEC) as 5% at the furthest receptacle in a branch wiring circuit. For example, in a 120 V/15 A circuit, there should be no greater than a 6 V drop (to 114 V) at the furthest outlet, with the circuit fully loaded.

To put it simply, excess voltage drop can reduce the operating efficiency of motors, lights, appliances, and other electrical equipment. If too much voltage is lost while passing through wires, equipment may not function properly, or at all. For certain equipment such as pumps, large motors, or machines that use compressors, even a small loss of voltage can be problematic. Keep in mind that voltage drop also generates heat, which can build up in wires or cables and damage the insulation, ultimately leading to safety issues such as fire and shock. Let’s take a look at the four main factors that affect voltage drop, and how to keep it to an acceptable minimum — defined by the National Electrical Code (NEC) as 5% at the furthest receptacle in a branch wiring circuit. For example, in a 120 V/15 A circuit, there should be no greater than a 6 V drop (to 114 V) at the furthest outlet, with the circuit fully loaded.

When current passes through wire, it is pushed along by electrical potential, or voltage, which must exceed a certain level of opposing pressure from the wire itself. Voltage drop is defined as the amount of electrical potential loss that is caused by the contrary pressure of the wire. The four chief variables involved in voltage drop include the wiring material, diameter, and length, and the amount of current being carried. The current carrying capacity of a wire is often called ampacity, which stands for ampere capacity.

With regard to the wiring material, copper and aluminum are widely used due to their excellent electrical conductivity and relatively low price compared with more expensive options such as silver or gold. Copper will experience less voltage drop than aluminum for the same wire length and diameter, as copper is a better conductor. Next, a larger wire size (diameter) will have less voltage drop than a smaller size of the same length. Wire length is also a key factor. A shorter wire will have less voltage drop than a longer wire of the same diameter. Finally, the amount of current being carried will affect voltage drop levels. An increase in current leads to increased voltage drop, but just how much depends on the wire’s ampacity, which in turn depends on variables such as wire material and temperature.

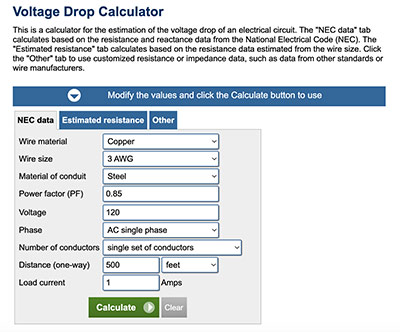

One of the easiest ways to decrease voltage drop is to increase the size (diameter) of your wires or cables, which will lower the resistance of the overall wire length. Take into consideration that a larger copper or aluminum cable will add cost, so be sure to calculate voltage drop in order to specify a properly sized wire. Online voltage drop calculators and wire manufacturers are a good place to start.

Leave a Reply

You must be logged in to post a comment.