A new particle-free energy chain for cleanrooms has been developed by igus that allows for safe cable guidance in compact installation spaces, providing a cost-effective alternative to ribbon cables.

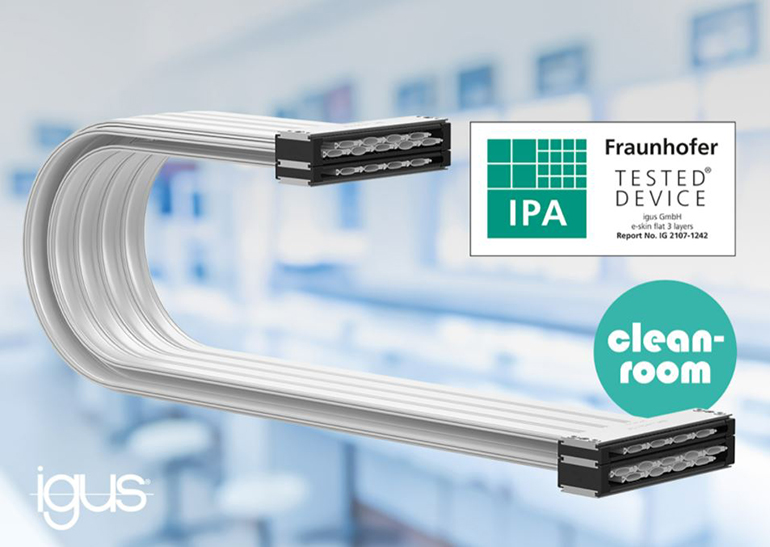

The e-skin flat energy chain from igus is a modular design and in the Fraunhofer cleanroom test, demonstrated cleanroom performance in accordance with ISO Class 1 as a single-layer and as a three-layered, ready-to-connect e-chain system. igus, which is based in Cologne, Germany, runs its North American operations out of Providence, R.I.

The e-skin flat is designed for cleanrooms, where LEDs, microchips and semiconductors are manufactured in areas characterized by little space and absence of particles. In order to guide cables safely in compact installation spaces, the e-skin flat allows cables and hoses to be quickly installed into flat profiles and replaced during maintenance.

The e-skin flat is designed for cleanrooms, where LEDs, microchips and semiconductors are manufactured in areas characterized by little space and absence of particles. In order to guide cables safely in compact installation spaces, the e-skin flat allows cables and hoses to be quickly installed into flat profiles and replaced during maintenance.

igus uses a special high-performance plastic that has been regularly tested in the in-house cleanrooms laboratory throughout the entire development process. The e-skin flat is resistant to wear and abrasion, and its single-layer variant has been Cleanroom Class 1 since its introduction in 2019.

The invention also won over the 2021 REINER! Awards judges. “Since the e-skin flat is rarely installed with just one layer, but often with three, we wanted to achieve the highest cleanroom class possible,’’ said Peter Mattonet, cleanroom technology industry manager at igus GmbH.

The Fraunhofer Institute IPA tested an e-skin flat energy supply system with three layers of four chambers each, including support chains, cables and hoses. During operation, the testers checked emissions at three key points. In the test, the chain was the only cleanroom energy chain to receive ISO Class 1 according to ISO 14644-1 with a bend radius of 70 millimeters.

“The e-skin flat stands out as a particle-free, compact energy supply system for the cleanroom, that saves the user space and therefore greatly reduces costs,’’ Mattonet said.

The e-skin flat energy supply system is configurable depending upon the application. It can consist of up to six chambers per layer. Three-layered structure supports chains in the lowest layer, which ensures chain stability.

igus has also developed the CFCLEAN series specifically for use in the e-skin flat. The cable cores can transmit energy and signals for motor control, bus and ethernet. The user can receive, upon request, a complete cleanroom system that is certified and ready to connect upon arrival.

igus Inc.

www.igus.com/info/e-skin-flat

Leave a Reply

You must be logged in to post a comment.