As bus products evolve to faster and more environmentally-friendly products, the need for backward compatibility is important.

Contributed by Neal Allen, Vice President of Engineering, Helukabel USA

Despite the move towards Ethernet-based protocols, controls manufacturers continue to avoid standardization and create their own proprietary bus cable. This article will explore how the industrial marketplace has addressed the bus network cable solution.

After working in both the manufacturing and marketing sectors for two types of serial data cables – computer bus and industrial bus – it is interesting to note that the computer industry has had greater success in achieving non-partisan, industry-wide standards such as SCSI, Fiber Channel, Ethernet and USB, where the industrial side tends to be a more independent and produce cable products specifically for their brand names. The fact that the Institute of Electrical and Electronics Engineers (IEEE) is the independent governing body for local area network (LAN) is one main reason the protocol continues to be successful many years later and generic products can be purchased very conveniently.

More often than not, the products used in modern industrial controls are generated through established organizations that create products to benefit a specific manufacturer. The organizations usually consist of the connector and cable manufacturer, and in some instances, the software manufacturer. The problem is that this dependence on the demands of each manufacturer creates specific products and limited commercialization to make them readily available and accessible to the end user.

In the industrial world, there are numerous variations due to different speed and/or impedance requirements, ranging from 100 to 150 ohm. The interface has become so diversified that cable manufacturers sometimes design a hybrid cable for automotive manufacturing plants that has components using PROFIBUS, DeviceNet, Ethernet and INTERBUS protocols all in one cable. This allows them to be able to connect their PLC logic to whatever controls line happens to come in on the next machine or contract.

Some common bus types and affiliated sponsors for the industrial bus network are:

| Bus Type | Governing Body | Affiliated Sponsors |

| AS-Interface | AS International | Balluff, Festo, IFM Electronic, Leuze Electronic, Pepperl+Fuchs, Sick, Siemens, Turck, Visolux (now part of the Pepperl+Fuchs group) and Swiss (Baumer and Elesta) companies |

| CC-Link | CC-Link Partner Association (CLPA) | ABB, Beckhoff, GE Mitsubishi and Schneider Electric |

| CAN bus | Bosch | |

| FOUNDATION Fieldbus | The International Society of Automation (ISA) | |

| INTERBUS | Phoenix Contact | |

| Modbus | Modbus.org | Square D, Schneider Electric |

| ControlNet, EtherNet/IP & DeviceNet | Open DeviceNet Vendors Association (ODVA) | Omron, Rockwell Automation, Square D and Westinghouse Cutler-Hammer |

| PROFIBUS/PROFINET | Process Field Bus | Siemens |

| Sercos (Serial Real-time COmmunication System) | Sercos International | ABB, AEG, AMK, Robert Bosch, Indramat, and Siemens |

Protocol standardization

With the acceptance of Ethernet in the front office and the need for plant-wide system compatibility, the industry wants to provide a more open architecture interface. Ethernet (100 ohm) protocol seems to be a good choice for the industrial workplace. Additionally, the higher information speed requirements (up to 10 Gig), added diagnostic feedback of controls, and interest in motor feedback for both servo and VFDs, makes Ethernet a good choice to offer for the performance required.

Unfortunately, the requirements are still driven from the controls manufacturers’ system trademark. PROFIBUS is now PROFINET, CC-Link is now CC-Link IE, DeviceNet is Industrial Ethernet, Sercos is Sercos III and Foundation Fieldbus is Foundation Fieldbus HP, to name a few. Many systems on the shop floor are gravitating to the faster office-based Ethernet architecture as systems become more compatible with companywide operating systems and architecture. The compatibility is a little less commonly known, probably for marketing reasons. The plug-and-play aspect also plays a part in the manufacturer’s needs to avoid commoditizing the product.

Independent special interest groups have started to recently appear and are working to shed exclusivity for system compatibility of conventional Ethernet. Ethernet POWERLINK Standardization Group (EPSG) has developed a formidable product offering with data transmission speeds of 100 Mbit/sec. They are finding component manufacturers willing to adopt their standard Ethernet protocol into their systems.

Connector standardization

As the Ethernet protocol interest grows, so does the standardization of connectorization being accepted in the industry as major device vendors gravitate to metric-type connectors typically known as DIN style, e.g. M-8 Micro, M-10 and M-12 mini. The RJ45 is also used but it is modified to provide larger gauge compatibility, harsh environment and shielding capabilities.

Market-based bus interest

The servo market has also seen a move to the Ethernet-based architecture as it further develops the feedback and network interface. Sercos III has been an acceptable interface to network servo interface applications for some time, and Siemens uses the Drive-Cliq Ethernet-based system to provide feedback for their servos. Many other servo drive manufacturers continue to slim down the servo feedback side of the drive system to a 100-ohm Ethernet-type design.

As you can see, Ethernet-based architecture is a good choice for serial bus networks since the compatibility and standardization of Ethernet from the computer side found in the front office drives the manufacturing side to generic products. The marketing side of the controls and drives industry still continues to produce proprietary products (protocol tested) to help with their exclusivity. The members of the organizations that write the standards develop the cable requirements that are exclusive to the brand. Having a diversity of protocols allows cable manufacturers to offer many different cable systems. Configurations also help the bottom line as each architecture has unique conductor configurations and electrical requirements.

As a point of comparison, non-factory, market-based bus development can look to the agricultural industry for how to standardize a certain protocol.

The Agricultural Industry Electronics Foundation (AEF) was founded because of the incompatibility between tractor and implements required the need to standardize on a protocol. ISOBUS, especially ISO 11783, is the worldwide standardized communication interface between tractor and implements, and is a similar architecture to the CAN bus protocol derived from IEEE 802.3. This is a better approach to the problem of industry protocol standardization since it allows for common bus requirements for the industry to be homogenized and not diversified.

Moving forward

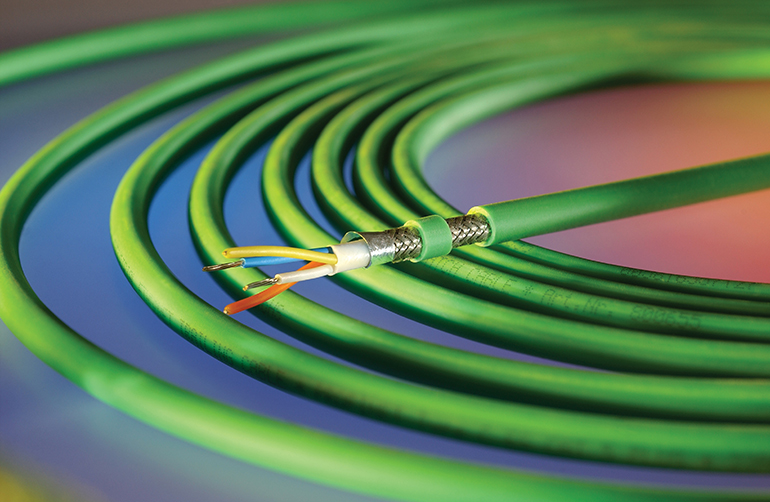

The goal of the various bus products and designs developed over the last 50 years was to find a cable product capable of fast computer speeds that could withstand electrical noise and applications in harsh environments. The technology continues to be developed and is moving into the fiber optic space due to their lower noise performance. As bus products evolve to faster and more environmentally-friendly products, the need for backward compatibility is important. Similar to Ethernet, backward compatibility from higher categories must be used in equipment with a lesser category level rating, which will allow more standardization of the cable product and better availability.

Large volume cable manufacturers continue to provide numerous bus products to their customers since they tend to members of many of the bus organizations. The major suppliers from a private label perspective tend to be job-based suppliers and are not common names in the distribution/integrator/MRO marketplace. High-volume manufactures deal with many customers and their applications, and find it very dynamic with little effort to unify the industry under a single, accepted protocol. With the exception of the automotive and agricultural industries, there is not much market-based development for standardization either. Ethernet-based protocol appears to be the eventual standard of choice given the volume and performance advantages it offers. Until then manufacturers should continue to provide bus cable products in order to service the needs of industrial customers.

Helukabel USA

helukabel.com

Leave a Reply

You must be logged in to post a comment.