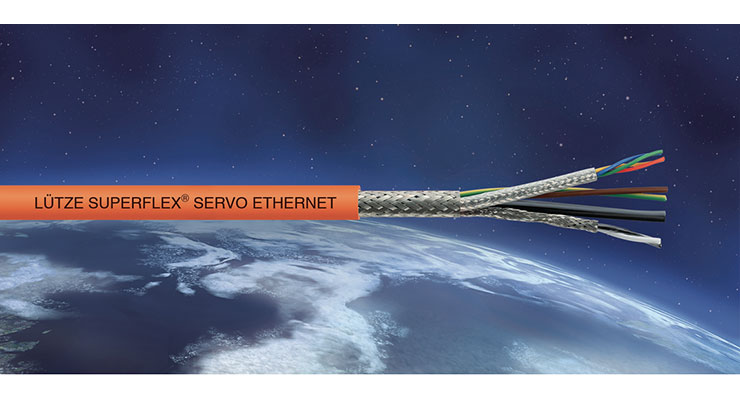

The new LÜTZE Superflex one cable solution with an integrated Ethernet element is suitable for power supply, data transfer and controlling brakes in servo drives. They also comply with the new Siemens and Indramat (Bosch Rexroth) standards.

Thanks to the PUR sheath and sliding wire insulation, the new cables are ideal for the challenges faced when using C-tracks in the machine and plant construction sector, and in transport and conveyor equipment, for example. The LÜTZE Superflex Ethernet hybrid cables can replace several cables at once — power supply, brakes and digital feedback via Ethernet are bundled in one cable to save space. This saves both time and costs associated with procurement, installation and maintenance.

Thanks to the PUR sheath and sliding wire insulation, the new cables are ideal for the challenges faced when using C-tracks in the machine and plant construction sector, and in transport and conveyor equipment, for example. The LÜTZE Superflex Ethernet hybrid cables can replace several cables at once — power supply, brakes and digital feedback via Ethernet are bundled in one cable to save space. This saves both time and costs associated with procurement, installation and maintenance.

They are also much lighter and therefore put less strain on the C-track. Thanks to the space savings in the C-track, this can now be designed to be smaller which also saves costs and because of the integrated Ethernet data cable, a connection to the existing control systems is much easier to create. This enables fast and safe data transfer within the company network and various numbers of wires, diameters and rated voltages ranging from 300 – 1,000 V.

All cables are available for immediate ordering. The LÜTZE OCT (One Cable Technology) Ethernet hybrid cables are designed for operation in challenging industrial environments, for example when using aggressive cooling and lubrication agents. The LÜTZE Superflex hybrid cables come in 7.5xD to maximum 10xD, and therefore offer above-average flexural fatigue strength for long-term and fail-safe use in the C-track. The braided shield, optimized for continuous use, offers high active and passive interference resistance (EMC).

The application temperature range lies between –40° and 80°C and the halogen-free and RoHS-conform hybrid cables meet the requirements of the UL approval according to cURus.

The role of servomotors has changed considerably — they have become versatile actuators in networked and flexible Industry 4.0 production environments. The basis for this are digital interfaces for motor-controller communication.The advantages include 50% fewer lines (two become one), less space required and lower assembly and maintenance costs. In brief, this means better efficiency and safety. The hybrid lines are therefore becoming more popular, and LÜTZE’s One-Cable-Technology offers optimal cable solutions for use in the machine and plant construction sector as well as the robot industry.

Lütze Inc.

www.lutze.com

Leave a Reply

You must be logged in to post a comment.