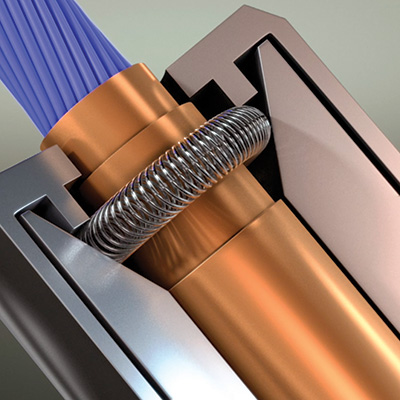

Canted coil springs shield sensitive electronics from the harmful effects of EMI/RFI. Featuring independent coils that serve as multiple contact points for optimal conductivity and/or grounding, these springs ensure consistent, reliable connection with mating surfaces, even under shock and vibration. These springs feature precisely engineered coil angles.

Canted coil springs are ideal for use in high-frequency, small-package applications. Because they can be used to shield and mechanically fasten with precisely controllable insertion and removal forces, they reduce system weight, size and complexity.

Common applications include cabling, coaxial and electrical connectors, connectors, connect/disconnect assemblies, electronic enclosures, waveguide flanges, and more.

In addition to shielding, they hold, latch and lock. They feature customizable mechanical forces, and their electrical properties can be “tuned” to meet specific impedance requirements.

Offering unique deflection and force behavior upon compression, the springs are available in a variety of configurations and coil shapes, and with various options:

- As closed rings or straight lengths

- In a variety of sizes

- In a variety of materials, including copper alloy and stainless steel

- With gold, silver, nickel or tin platings for optimal conductivity, galvanic compatibility and corrosion resistance

Supplying near constant force over a large compression range, these springs provide consistent shielding despite surface irregularities and tolerance variations.

Additional features of canted coil springs include:

- They act as a latching component, providing an audible click that confirms secure connection with no threading and easy removal

- Conductive/shielding properties provide protection against cross-talk, and interference from other devices in use

Key benefits of canted coil springs include:

- 3-in-1 functionality: Shielding, conducting and connecting while reducing weight, size and complexity of designs

- Resistance to compression set for longer service life (as compared with elastomers and fingerstock)

- Individual coils exert near constant force

- Compensation for misalignment and surface irregularities

- Ability to enable tool-less modular designs

- Easy maintenance, part-switching

Information courtesy of Bal-Seal Engineering

Leave a Reply

You must be logged in to post a comment.