Contributed by Frances Richards

Electromagnetic interference, or EMI, is an unfortunate fact of life in industrial environments due to the wide variety of equipment and devices operating in close proximity. Every piece of electric or electronic equipment generates signals that can interfere with other nearby machinery, potentially causing suboptimal performance or even total failure. And while the idea of eliminating EMI is a lofty goal, a more realistic path is to reduce this interference to an acceptable level.

EMI may be either conducted or radiated. With conducted EMI, noise is passed through wires and cables from the source to the receiver or victim device. Power lines, especially ac lines, are a key source of EMI due to the noise generated by all the devices connected to the line, such as motors and switching power supplies. Generators, variable frequency drives, soft starters for motors, arc welding equipment, and bulb ballasts are other common sources, and let’s not forget about mobile phones and WiFi networks. Subpar grounds are yet another major source of conducted EMI. In contrast, radiated EMI occurs wirelessly with noise being transmitted from the source to the victim during wireless signal transmission. This is often called near-field interference and includes crosstalk among the various wires inside a cable.

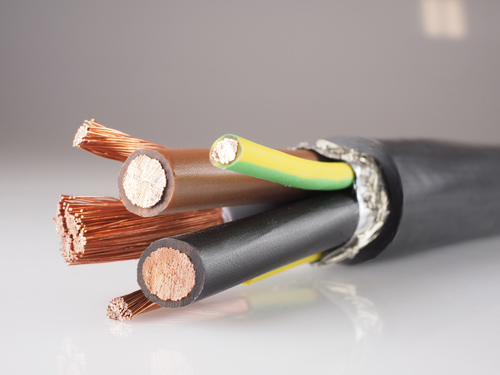

Managing EMI involves taking different approaches regarding the emitting and receiving devices. Easy fixes involve actions like creating more space between source devices and victims, turning one of the devices 90°, and rerouting cables. More sophisticated solutions involve filtering, shielding, and grounding. For example, filters are often added to cables and connectors on lines going into and out of circuits. Because cables tend to act as antennas and radiate a huge amount of noisy signals, they are known culprits when it comes to EMI — as are their connectors. Using shielded cables will go a long way toward minimizing EMI. Coaxial cable is a good choice for instrument signals, as is twisted pair shielded cable. Twisting helps cancel the magnetic fields generated by each wire, while adding a shield safeguards the cable from EMI in addition to supplying a path for EMI current to travel to ground.

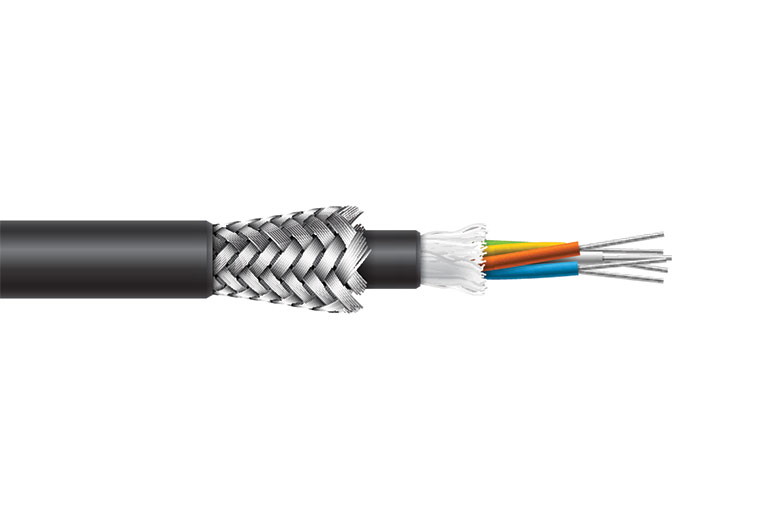

The best shielding option, whether foil or a braided shield, will be determined by factors such as the operating environment, flexibility required, and cable strength. Foil shields are less expensive and use a thin layer of metal reinforced with a polymeric layer (often aluminum plus mylar composite tape) to ensure 100% shielding, although cable flexibility may be reduced. Braided shields made of woven wire mesh (using bare or tinned copper wires) provide roughly 95% coverage due to spaces in the braids, but offer better conductivity than foil options. Be sure to ground the shielded cable’s drain wire for it to function properly, as the shield’s role is to reflect signal interference as well as pick up noise and conduct it to ground.

Another important strategy for minimizing EMI is to route signal cables separately from power and motor cables. These different types of cables should be run in separate conduits or at least keep the following recommended distances: 4 in. between signal and power cables for drives below 20 A; 6 in. for 40-A drives; and 8 in. for 80-A drives. If instrument wiring must cross over power wiring, do so at a 90° angle and keep as much separation as possible. Finally, avoid creating loops in your wiring — cable should be run as straight as possible. Following a few simple tips will go a long way toward keeping EMI at a manageable level in your industrial cable layout, helping both wired and wireless equipment to function at its best.

Leave a Reply

You must be logged in to post a comment.