For cable manufacturers, trends toward faster and more compact systems continue to reign. Suppliers to motion control systems, such as Helukabel, respond with cables for industrial automation that can transmit data in real time.

“We supply multiple motor manufacturers worldwide with feedback and signal cables in all variations — stationary, continuous flex and torsion rated. In distributed motion control we carry a wide range of products for that market, which includes Industrial Ethernet, PROFIBUS and PROFINET, Mod Bus, CC-Link, DeviceNet and CAN bus to name a few. Our latest offering is ISOBUS for use with trackers and their implements in the agriculture industry. We support various system architectures that are designed for use with Rockwell, Siemens, Schneider, Danaher, SEW, Lenze and many others,” said Neal Allen, Vice President of Engineering.

Additionally, the company has begun to manufacture Category 6 cables with combined power and data conductors, as well as hybrid I/O cables, said Gordon Post, Regional Sales Manager – Michigan.

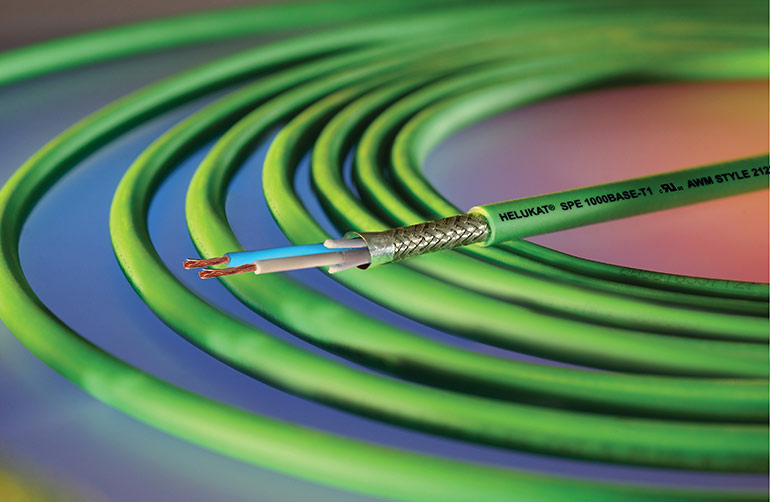

When it comes to the IIoT and increasingly networked manufacturing, Horst Messerer, Product Manager – Data, Network, Bus, said that the general trend is faster acceleration and higher speed with more bending cycles. “Also, more small machines are requiring cables with smaller bending radius or lightweight constructions, e.g. single pair Ethernet, where only one pair of conductors is required to transmit data up to 1Gbit depending on cable constriction and transmission length.

Messerer noted that new mating interface standards, such as ix Industrial and SPE, are the latest connectivity standards shaping the market. For example, Post added that there is growing interest in Helukabel’s TOPSERV PUR Hybrid, which is the company’s offering for single cable motion control applications that require the use of servo motors.

“Smaller sockets on the devices allowing smaller PCBs mean less material and smaller housings,” Messerer said. “Additionally, both of them provide better protection against vibration compared with the traditional RJ45 connectors. In the case of SPE, the cable will have only one pair which will reduce weight, and provide smaller bending radius due to the reduction in materials used.”

Over the past few years, the need for hybrid cables has continued to grow, where data and power/control is combined in one cable (one-cable solution or technology). “In the past all drive manufacturers had two cables: one for data and one for power. Today, all new motion control systems are using Ethernet protocols, which is allowing for the transmission of data in real-time. In the past they used either analog or bus technology, which is not capabilities to transmit in real-time,” Messerer said. “Furthermore, there is a clear trend to halogen-free solutions where there is less fume or toxicity compared to PVC compounds. Finally, the theme of being able to recycle compounds is coming more and more into play.”

Helukabel

www.helukabel.com

Leave a Reply

You must be logged in to post a comment.