Military aircraft manufacturers have accepted the practice of replacing microwave assemblies because they get damaged during installation in airframe platforms. Damaged airframe assemblies can lead to compromised signal integrity and failures over time, especially when exposed to normal flight conditions combining rapid changes in temperature and pressure with potential contamination from fuel, oils and fluids. Installation damage can also compromise the cable’s vapor barrier, resulting in performance that can degrade unpredictably with rapid pressure and humidity change.

Damage caused during installation can lead to system failures, which result in additional costs due to re-testing, delayed production schedules, increased maintenance downtime, and ultimately microwave assembly replacement. Therefore, manufacturers need a low-risk solution that withstands the rigors of installation and reduces the cost of ownership.

The answer comes from W. L. Gore & Associates (Gore), Landenberg, Pa., which designed a simulator to evaluate the stress of installation on microwave airframe assemblies. By comparing signal integrity before and after installation, Gore can engineer assemblies that withstand airframe installation as well as the demands of the aircraft’s flight envelope. This in turn helps to minimize the risk of cable assembly damage or failure during installation.

Because nearly one-third of cable failures occur during installation, this is a crucial risk factor to minimize. Damaged airframe assemblies can lead to compromised signal integrity and failures over time, as well as additional testing, maintenance and replacement costs. With the new Cable Installation Simulator, military and civil aircraft manufacturers can be confident they are getting a reliable cable assembly solution that withstands the rigors of installation and reduces the total cost of ownership.

Prior to installation in the simulator, new cable assemblies are tested to verify the insertion loss and Voltage Standing Wave Ratio (VSWR) over a given frequency range. For example, when testing an assembly rated at 18 GHz, insertion loss and VSWR are recorded over the range of 0.0225 to 18 GHz. This information serves as the baseline to evaluate any performance change after being routed through the simulator.

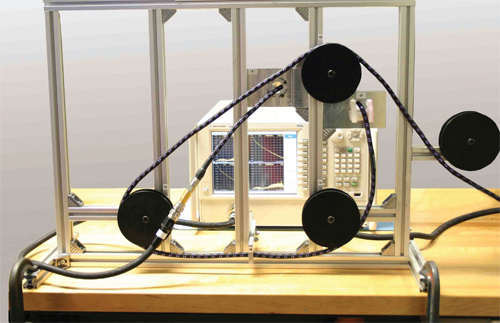

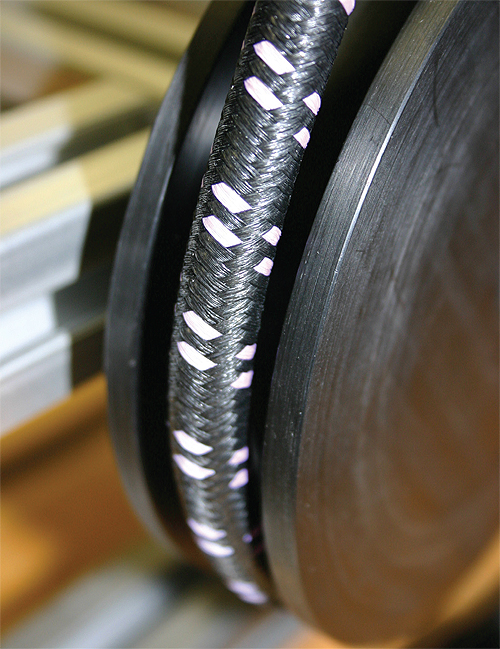

Gore’s Cable Installation Simulator replicates the conditions a cable assembly experiences while being routed during installation in an aircraft. The device uses four mandrels to simulate routing an assembly around the internal structure of an airframe, Figure 2. The mandrels replicate minimum bend radius conditions that the assembly will encounter in an aircraft.

Several routing guides are used to induce torque into the assembly as it is pulled through the simulator, Figure 3. Next, the assembly is pulled through an abrasion bar to simulate routing across sharp edges or through access holes in the airframe structure, Figure 4.

A tensile force of 20 to 40 lb is required to pull the assembly through all the simulator features that mimic typical installation practices. The assembly is connected to a digital force gauge to measure the force applied.

After being fed through the Installation Simulator, the assembly is ready for testing. The assembly is connected to a Vector Network Analyzer (VNA) to test the insertion loss and VSWR, and the results are compared to the baseline results of the assembly tested prior to installation. Depending on the results of the test, the assembly may be routed through the simulator multiple times and re-tested to verify its durability.

Use of the Installation Simulator gives aircraft manufacturers and installers evidence that their assemblies will provide the same level of electrical performance after installation as when they are brand new. And they can be assured that the assemblies will continue to perform reliably throughout the service life of the aircraft.

“Aircraft manufacturers need reliable solutions that can be installed deep within an aircraft and left there for the life of the platform. Therefore, we want to create ‘fit and forget’ solutions that will survive the demanding environments within an aircraft,” said Jim Foreman, product manager at Gore.

“We are committed to designing next generation products that solve key challenges, and mitigate risk for aircraft, said Paul Pino, Lead Principal Design Engineer at Gore, “To do this, we test and simulate real world conditions to ensure that our products do what we say they will do, consistently and reliably even in harsh conditions.”

W.L. Gore & Associates

www.gore.com/simulator

Leave a Reply

You must be logged in to post a comment.