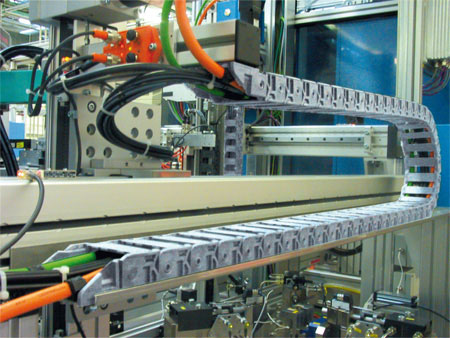

With ever-increasing speeds and higher load-carrying requirements at continually decreasing weights, cable carrier manufacturers are looking to material advances to help deliver solutions for completely new applications.

Cable carrier use is increasing especially in motion systems, said David Smith, director of sales, KabelSchlepp America, a division of U.S. Tsubaki Power Transmission. With so many motion systems becoming larger as well, manufacturers must also find new ways to improve the operating performance of long-travel cable carrier systems.

“Much of the design changes for carriers are currently in the material we use. We are constantly looking for material to improve performance in a large variety of environment extremes. This improved material selection now allows us to use cable carriers in environments that would not have been previously possible,” Smith said. “We are also working to reduce the noise that cable carriers generate to improve the work environment. To help with this goal we have found a variety of ways to dramatically lower the noise that a traditional cable carrier generates.”

Richard Deutsch, general sales manager for Murrplastik Systems, agreed, adding that, “materials have evolved to allow lighter yet stronger cable carriers. Specialty designs should be considered for applications that require chemical resistance, conductivity, flame resistance, extreme loads, or adverse environmental influences.”

Mark Cunningham, sales manager, Gortrac Div. of Dynatect Mfg., said that not only must these designs be lightweight, they must also be robust and able to accomplish longer travels at higher speeds. “To deliver cost-effective solutions for these application challenges, designers are using non traditional approaches,” he said. “Some examples are alternative plastic materials, hardened steel components and mechanically actuated support systems.

“In addition to advances in CAD/CAM, 3D FEA and Rapid Prototype Technology, specialty polymers and metal coatings have led to innovative carrier solutions in applications with heavy corrosion or salt spray resistance, ESD and multi axis requirements,” Cunningham added. “Automated guidance systems have also greatly increased travel and velocity requirements.”

Deutsch also said that these material advances have made carriers easier to use. “The functionality and easy assembly of each and every component part has allowed modern cable carriers to meet a wide range of requirements,” he said. “Innovations in end brackets, strain reliefs, horizontal and vertical separators and guide channels have greatly improved the ease of use and variability of design.”

Opening whole new applications

These innovations have led to greater use of cable carriers in applications that just weren’t possible before.

Most industries, including automotive, medical, food and beverage, aerospace, semiconductor, machine tool, agriculture and robotics, are all looking for improvements in cable carriers in terms of materials, noise reduction, longevity and ease of use, said Deutsch.

Specifically, he said, “Automotive, machine tool and robotics are looking to have more precise control over movements and processes as well as better feedback of those processes. This in many cases requires more components and control sensors, which in turn requires more cables and cables that are more flexible.”

Without these material advances, some applications would just not be possible, said Deutsch. “Murrplastik has a customer that required extremely high speeds, high acceleration and high G forces. This required a special type of chain configuration to meet all of the requirements. The materials used were not available 10 years ago. The capabilities of this chain will also increase the life cycle of the cables being used.”

Cunningham said that until recently, oil and gas exploration, drilling and refining had been fueling the development of large and specialized carriers before the drop in prices this year. As this has slowed down, medical applications have increased for Dynatect.

“As the use of automation in the medical equipment industry increases, there is increasing demand for cable and hose carriers. Applications range from guidance systems on mobile imaging equipment to dressing and securing air, fluid and electrical lines in automated surgical equipment to more complex balancers and manipulators in high tech operating rooms,” Cunningham said.

In one example, Dynatect worked with a customer to design the carrier system for a mobile CAT scan machine designed to move between examination and operating rooms. “While the initial design was a fairly standard carrier, as the project unfolded, the design evolved,” Cunningham said. “New requirements for washdown and safety led to the development of custom covers and a hanging support system actuated by the natural polygon effect of the carrier in motion, to prevent it from falling on a patient in the event of seismic activity like an earthquake.

“A tight design-to-build timeframe led us to use rapid prototyping technology to prove components prior to tooling,” he continued. “This would not have been possible ten years ago.”

For KabelSchlepp, the aerospace industry is key, said Smith. “The aerospace industry seems to be very active in regard to plant updates and equipment improvements,” he said. “In addition to the manufacturing need, we also see that cable carriers are being installed in large commercial aircraft. With the increased technology in each passenger seat, aircraft are beginning to need cable carriers to properly control all the cables.”

A recent example of this need was with a completely custom cable carrier design used to supply power to a device that drives around commercial aircraft sandblasting the existing paint in preparation for re-painting.

“The total travel was more than 100 m and the cable carriers had to be able to handle a large variety of degrees of motion and also be completely retracted to keep floor space clear,” Smith said. “This would not have been possible for a cable carrier 10 years ago.”

Leave a Reply

You must be logged in to post a comment.